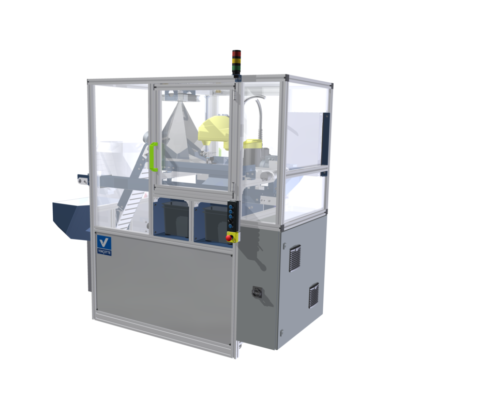

Unpacking Machine

SMO developed an Unpacking Machine for Vinçotte, Controlatom division in Vilvoorde. All dosimeters that the company processes were previously unpacked manually. This was a time-consuming job, so they searched a way to do this faster and automatically.

The machine is loaded with a dosimeters that have to be unpacked. Once they are loaded and the operator presses start, the machine carries these dosimeters piece by piece to the camera using conveyor belts. On the way to this camera, the packaged dosimeters pass an ion sprayer so that the static electricity is removed from the packaging. The camera recognizes the dosimeters and informs the robot where the grabber can pick up the dosimeter.

Dosimeters that are not recognized (for example, a broken package, an elastic band around the meter) are passed through and ignored by the system. These end up in the lifting hopper, but nothing else is done with this.

The dosimeters that the robot does grab are held above an RFID reader so that they are identified, and are then taken to the unpacking station. Here they are unpacked and picked up again by the robot. The unpacked dosimeters are then transported by the robot to a funnel that deposits the dosimeters in a curb box. The plastic packaging that has just been removed is suctioned off by a vacuum cleaner and collected in a large bag.

The RFID reader communicates with underlying software, and can also decide that a dosimeter may not be processed. The meters are then kept aside in a separate collection bin.

Want to know more? Contact SMO for more details and prices.